Introduction

In the vast realm of pharmaceuticals, where precision and accuracy are paramount, human errors can have far-reaching consequences. These errors encompass a spectrum of mistakes, from mislabeling medications to miscalculating dosages, each bearing the potential to impact patient safety, regulatory compliance, and a company’s reputation.

This blog post delves into the multifaceted nature of human errors in the pharmaceutical industry, shedding light on their underlying causes and exploring strategies to mitigate their occurrence.

Understanding Human Errors

Human errors, though inevitable in any complex industry, are especially critical in pharmaceuticals due to their potential to harm patients. These errors can emanate from various sources, ranging from cognitive limitations and insufficient training to communication breakdowns and process/system design flaws.

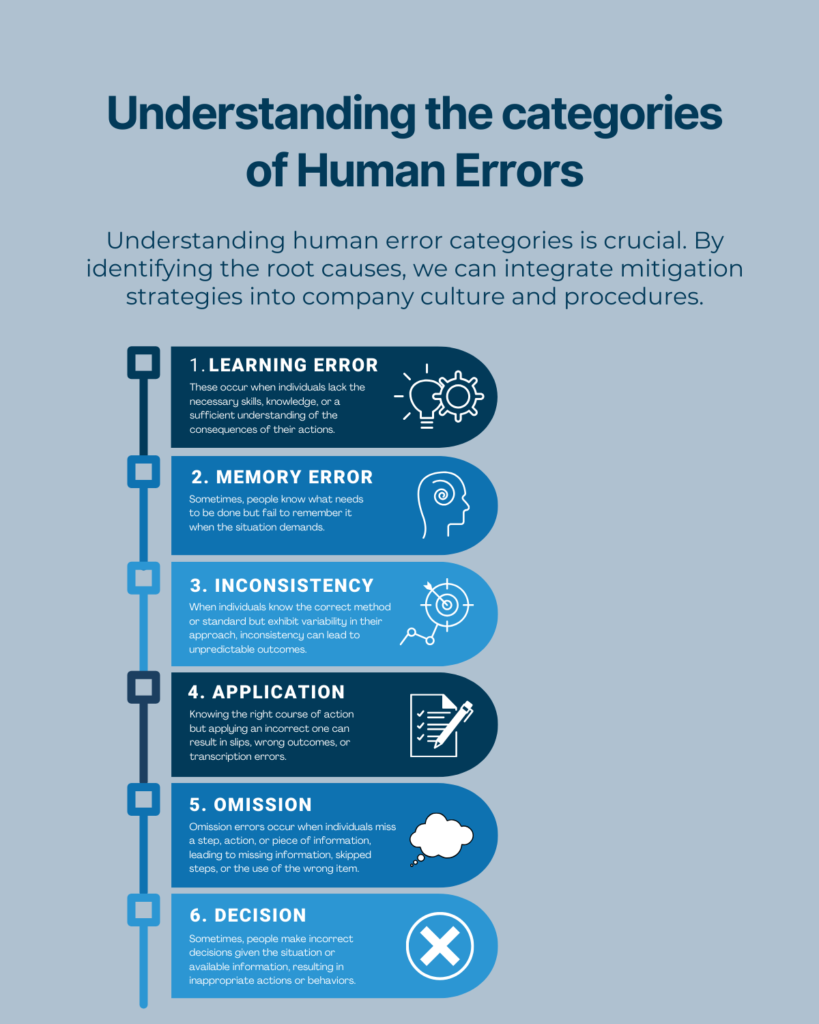

The Categories of Human Error

First and foremost, understanding the categories of human errors is paramount. By grasping the underlying reasons behind these errors, we can weave mitigation strategies into the very fabric of our company culture and procedures.

Below, we outline the categories of human errors:

- Learning Errors: These occur when individuals lack the necessary skills, knowledge, or a sufficient understanding of the consequences of their actions. To reduce learning errors, continuous training and education are key.

- Memory Errors: Sometimes, people know what needs to be done but fail to remember it when the situation demands. Employing memory aids, checklists, or reminders can help mitigate memory-related errors.

- Inconsistency Errors: When individuals know the correct method or standard but exhibit variability in their approach, inconsistency can lead to unpredictable outcomes. Establishing clear procedures and guidelines is crucial to reduce inconsistency errors.

- Application Errors: Knowing the right course of action but applying an incorrect one can result in slips, wrong outcomes, or transcription errors. Implementing verification processes and double-checks can be effective in preventing application errors.

- Omission Errors: Omission errors occur when individuals miss a step, action, or piece of information, leading to missing information, skipped steps, or the use of the wrong item. Robust procedures and thorough reviews can help prevent omission-related mistakes.

- Decision Errors: Sometimes, people make incorrect decisions given the situation or available information, resulting in inappropriate actions or behaviors. Encouraging a culture of open communication and collaboration can reduce decision errors by allowing for collective decision-making and feedback.

By understanding these common categories of human error and implementing strategies to address them, organizations and individuals can significantly reduce the likelihood of errors, leading to improved efficiency, safety, and overall performance in the company culture.

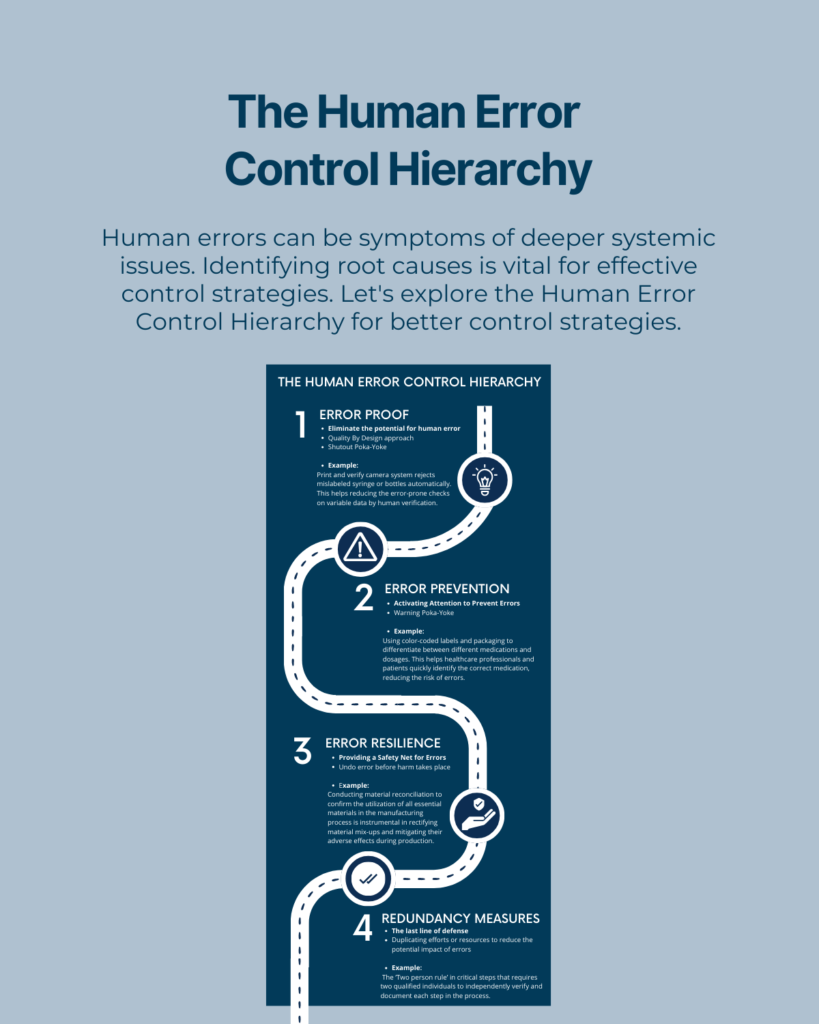

The Human Error Control Hierarchy

In any workplace, human errors can happen, but they’re often symptoms of deeper systemic issues. Understanding the root causes behind these errors is crucial for implementing effective control strategies. Underneath, we’ll explore the Human Error Control Hierarchy, a structured approach to managing and reducing human errors. Let’s dive into the hierarchy of control strategies:

1. Error-Proofing: Eliminating the Potential for Human Error

At the top of our hierarchy is error-proofing, the gold standard in preventing human errors. Also known as Shutout Poka-Yoke, this approach focuses on making it physically impossible to proceed if a step is missed or done incorrectly. It’s all about designing systems and processes in a way that leaves no room for error.

Think of printing and verification camera system that automatically identifies and rejects syringes or bottles with labeling errors, thereby diminishing the need for error-prone human verification checks on variable data.

2. Error-Prevention: Activating Attention to Prevent Errors

Next up is error prevention, a proactive approach that aims to catch errors before they happen. Often referred to as Warning Poka-Yoke, this strategy employs devices or systems that alert users to potential errors. These warnings provide immediate feedback, helping individuals correct their actions before mistakes can progress further.

Think of using color-coded labels and packaging to differentiate between different medications and dosages. This helps healthcare professionals and patients quickly identify the correct medication, reducing the risk of errors.

3. Error-Resilience: Providing a Safety Net for Errors

Error-resilience is about creating systems that allow individuals to undo errors before they cause harm. It acknowledges that mistakes can still occur despite the best prevention efforts. In such cases, having mechanisms in place to rectify errors promptly can be invaluable.

Consider conducting material reconciliation to confirm the utilization of all essential materials in the manufacturing process. It is instrumental in rectifying material mix-ups and mitigating their adverse effects during production.

4. Redundancy Measures: The Last Line of Defense

Finally, we have redundancy measures, which serve as the last line of defense against errors that manage to slip through earlier safeguards. These measures involve duplicating efforts or resources to reduce the potential impact of errors.

Consider the ‘Two-person rule’ in critical steps that requires two qualified individuals to independently verify and document each step in the process. Or backup systems and contingency plans. These measures can mitigate the effects of an error, helping to keep a situation under control when all else fails.

Conclusion

As Quality Assurance experts in the pharmaceutical industry, our mission is to ensure safety, precision, and quality at every step. Understanding the multifaceted nature of human errors and implementing a structured approach, such as the Human Error Control Hierarchy, empowers us to create a culture of excellence, where patient safety and continuous improvement are non-negotiables.

If you’re committed to reducing errors and enhancing patient well-being, let’s collaborate. Contact us today to explore how our expertise in Quality Assurance can benefit your business.